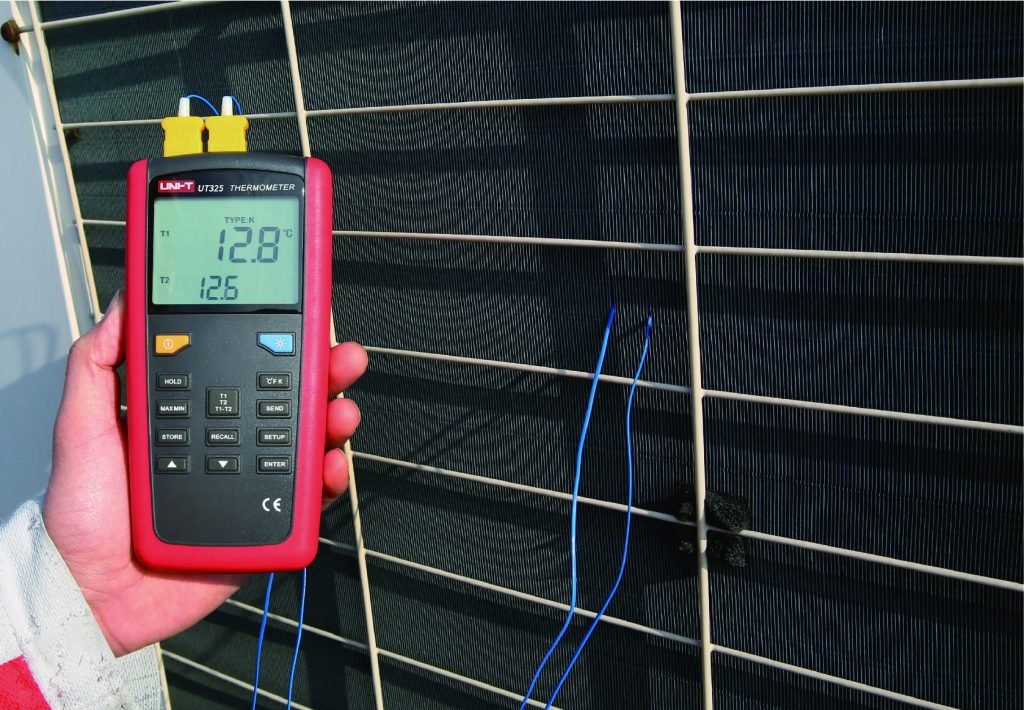

In recent decades, thermocouple thermometers have been inseparable in fields like manufacturing and research, and also in healthcare and food processing. The unique capability for the measurement of temperature with high accuracy, even in very aggressive environments, has made it versatile for many applications. This blog deepens your understanding of what a thermocouple thermometer is, how it works, its types, advantages, and practical applications.

What is a thermocouple thermometer?

A thermocouple thermometer is a temperature measuring device that utilizes a thermocouple as the sensor element. Thermocouples are basically composed of two dissimilar metals joined at one end, known as a junction. There exists an electromotive force (EMF) across a junction when there is a temperature difference between the hot and cold ends of this junction. This EMF gets converted into a reading of temperature.

Probably among these, thermocouple thermometers work effectively in a wide measurement range, have a fast response, and are able to accept external harsh conditions, making it suitable for industrial, scientific, and commercial applications.

How Do Thermocouple Thermometers Work?

The operating principle of the thermocouple thermometer is that of the Seebeck effect. It states that when a juncture of two different metals is subjected to differential temperature, then a corresponding voltage will be generated in the said juncture and is directly related to this temperature difference; thus, with appropriate calibration, one can determine the actual temperature.

The key components include:

- Hot Junction: Located in the medium whose temperature needs to be measured.

- Cold Junction: Kept at an already known reference temperature.

- Output Device: The device that converts voltage into a readable temperature value.

Thermocouple Thermometer Types

Thermocouple thermometers have a number of types that may be used according to specific applications, with regard to the operating temperature and/or characteristics of the materials involved. The following are some of the most commonly used thermocouples:

- 1. Base Metal Thermocouples (Types E, J, K, T):

Applications: Industrial ovens, HVAC.

Advantages: Inexpensive and durable for moderate temperatures.

- Noble Metal Thermocouples (Types R, S, B):

Applications: High-temperature industries in glass and steel making.

Advantages: Highly accurate in very hot weather conditions.

- Refractory Thermocouples (Types C, D, G):

Applications: Aerospace, vacuum furnaces.

Advantages: It can bear a temperature as high as 2300°C.

- Mineral Insulated MI Thermocouples:

Applications: Environments needing durability and flexibility.

Advantages include resistance against abrasion, vibration, and chemical exposure.

5.Special Thermocouples:

Application-specific designs for special needs of industries.

Advantages of Thermocouple Thermometers

Thermocouple thermometers boast a number of advantages that make them very common in many areas:

- Wide Temperature Range:

It can measure from cryogenic levels up to extremely high temperatures, reaching as much as 2300°C.

- Durability:

Resistant to harsh conditions, including extreme temperatures, pressure, and corrosive environments.

- Quick Response Time:

Ideal for dynamic processes requiring real-time temperature monitoring.

- 4. Versatility:

Available in different forms, materials, and configurations to suit specific needs.

- Cost-Effectiveness:

Generally cheaper than other high-accuracy thermometers.

Application of Thermocouple Thermometers

The versatility of thermocouple thermometers makes them an indispensable tool in many spheres of human activity, including the following:

- Manufacturing Industry:

- Monitoring the temperature of furnaces and kilns.

- Ensuring heat treatment processes with exact precision.

- Food and Beverage:

- Measuring cooking and storage temperatures.

- Assuring the compliance of food safety standards.

- Healthcare:

- Monitoring the process of sterilization in medical equipment.

- Used in lab applications for research and diagnostics.

- Aerospace and Automotive:

- Measuring engine temperatures.

- Monitoring material testing processes under extreme conditions.

- Energy and Power:

- Ensuring efficiency of turbines, boilers, and generators.

- Monitoring temperatures in nuclear reactors.

Key Considerations When Choosing a Thermocouple Thermometer

When selecting a thermocouple thermometer, consider:

- Temperature Range: Make sure it covers the range you need.

- Accuracy Requirements: Higher accuracy is critical in certain applications, such as research and healthcare.

- Environment: The degree of resistance to chemical exposure, vibration, or abrasion.

- Material Compatibility: The selected type of thermocouple shall be compatible with the measured medium.

- Calibration Standards: Choose those devices whose calibration standards are according to international standards, such as the IEC 60584 and ASTM E230.

Why Choose Tempsens Thermocouples?

Tempsens is a name synonymous with confidence in the field of temperature measurement, offering a wide array of thermocouple thermometers to suit varied requirements. With precision, durability, and innovation as the core focus, every product by Tempsens is manufactured to withstand the most adverse industrial conditions.

Some of the salient features of the thermocouples manufactured by Tempsens are:

- Compliance with international standards.

- Options for base metal, noble metal, and refractory thermocouples.

- Wide customization to suit unique industrial requirements.

Endnote

Thermocouple thermometers have a great reputation for their precision and reliability in temperature measurement in a wide range of applications. Their adaptability, along with strong performance, makes them an indispensable part of many industries globally. With the latest technology and high-quality products, Tempsens ensures that users get the most accurate and durable thermocouples to meet their needs. Whether it is temperature monitoring in an industrial furnace or ensuring food safety compliances, the right thermocouple thermometer makes all the difference between efficiency and success. Explore the range of thermocouple solutions to find the perfect match for your requirements.